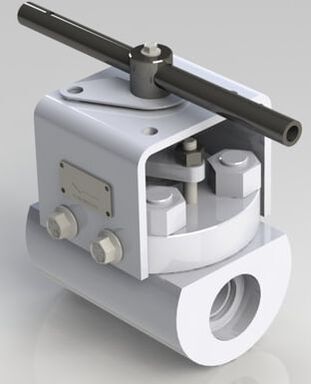

TE-4

|

Features:

|

- Downstream seats locked to prevent blowout in back pressure condition.

- Bonnet gasket is not susceptible to pipe stresses and memory, eliminating a potential leak path and re-alignment challenges. Inherent with 3 pc valve designs.

- Simple maintenance via top entry eliminates the challenges of realignment as is the case with 3pc designs.

- Truly in-line repairable design does not require spreading of piping system unlike in 3pc designs.

- Modular trim kit allows for simple, deliberate repair of a factory vacuum tested trim-set that is certified leak free vs. competitor design.

- Coating procedure applies our proprietary coating under compression vs. tension keeping the coating inherently on the ball and seats.

- Scalable design for use in larger applications such as main steam, BFW and all other applications in a power plant that can benefit from a smaller envelope, and quarter turn ease of automation.

- Quarter turn operation extends life of packing vs. pulling the stem through the packing gland in a Y-Globe operation.

- Quick, quarter turn operation of valve mitigates damage from high velocities across seating surfaces unlike in slow opening linear valves.

- Overall envelope dimensions compact vs. competitor design.

- ISO-5211 mounting bracket standard.

- Can be custom ordered with weld pups factory installed to eliminate field welding of dissimilar metals in transition areas ( ex. F91 to F22)

- “Fits only one way” lever handle

Size / Pressure Class:

Up to 4" (custom sizes available)

ANSI / ASME 150 - 4500

Standards:

ASME B16.34

Leakage:

Zero Seat Leakage: Type-tested with high pressure Nitrogen gas, achieving zero bubbles

Up to 4" (custom sizes available)

ANSI / ASME 150 - 4500

Standards:

ASME B16.34

Leakage:

Zero Seat Leakage: Type-tested with high pressure Nitrogen gas, achieving zero bubbles

-

REPRESENTATIVE G.A.D.

-

MARKET/APPLICATIONS

<

>

First valves installed in 2010

- Corrosive Media

- Erosive Liquids

- Entrained Particulates in Gases

- Power Generation

- PetroChemical

- Steam Services